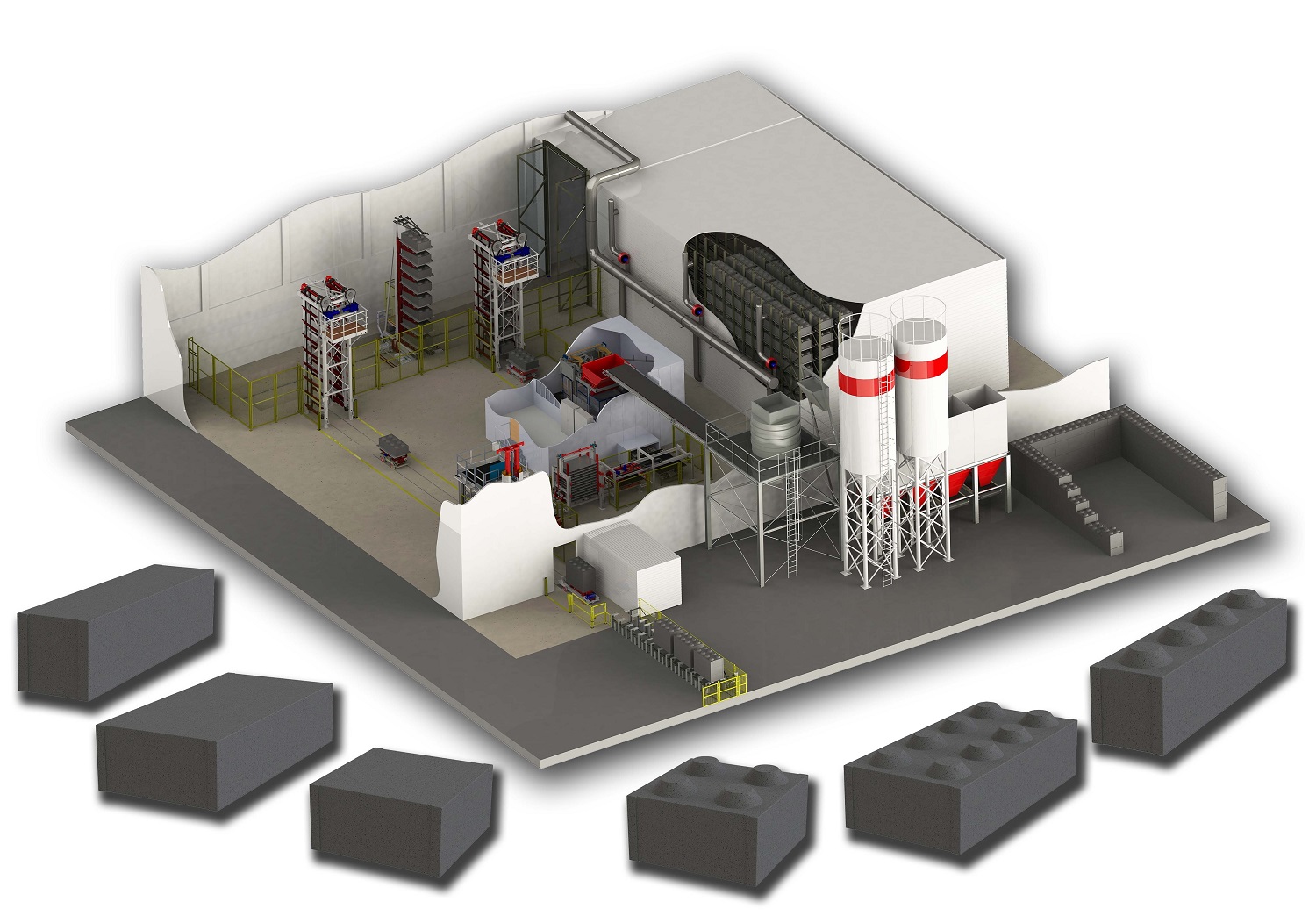

The production line is designed for production of concrete building blocks with the maximum size of 1600x800x470 (L x W x H). They are easy to be fixed and they can be used for building all kinds of structures like retaining walls, warehouse and hall walls, boxes and storage within the industrial areas. The produced elements, due to their suitable weight and shape (plugs/holes), can be stacked with no need for any binder. The production line allows to manufacture full elements with plugs, “halves”, finishing elements, elements with different widths and shapes depending on their purpose. The production process of the blocks makes it possible to successfully add various materials to the concrete mixture (in large percentage). These additional materials can come from recycling, what drastically lowers the cost of production.

The production line uses well-known and world recognized block machine Zenith 940, which ensures high quality of products and simultaneously high endurance of the products. The components of drivetrain and control system are of the highest quality: Demag, Nord, Bosch Rexroth, Siemens, Moeller, Leuze, Sick, IFM. All machines use proven solutions which guarantee uninterrupted production and simple control system for easy exploitation.

Simple curing system with isolated racks, controlled air circulation and temperature measurement reduces the time for curing process of fresh elements. The rack system is based on our innovative system Quicks. This profitably influences the final price while it still ensures the top level of durability parameters.

The production line was designed to minimize the investment costs. This was obtained mainly by innovative concept of machines layout, reduced number of machines and resignation of long and heavy product conveyors.

Additionally, the optimized solution for drivetrain was introduced. The innovative system ENH SDO for hydraulic systems was applied. This system is not only energy efficient but also eliminates problems with hydraulic oil heating up and maximizes the resistance to oil contamination. Moreover, it lowers the service cost of those systems.

The control system for the production line offers flexible and easy control and supervision over the machines due to the SCADA and HMI systems. The extended diagnostics of machines and applied electronic devices facilitates usage and maintenance. The remote access to the control system (via internet/GSM) enables quick support when needed.